Home » Applications » Why use Bypass in Variable Frequency Drive system?

Why use Bypass in Variable Frequency Drive system?

Although VFDs have become reliable devices in the last several years, some applications still require a back up system.

Some applications where bypass is required are those where downtime for any reason is unacceptable such as the ventilation of an operating room, computer room or clean room. Some industrial applications also require bypass to enable operation in the event of a VFD failure, and typically are requested on centrifuges, induced and forced draft furnace fans and pumps.

In commercial buildings, fire and safety requirements often call for bypass as part of a VFD package to insure the evacuation of smoke from a building after a fire. In such cases, bypass must allow for the remote control of the motor.

The bypass must switch the power supply to the motor between the variable frequency drive and the power line, but it also must be able to:

Many bypasses are sized to handle only the full load current of a motor and not the locked rotor current. These are less expensive contactors or switches but cannot act as motor starters. A bypass which is not horsepower rated must only be switched when power is off and therefore requires a motor starter upstream.

Some applications where bypass is required are those where downtime for any reason is unacceptable such as the ventilation of an operating room, computer room or clean room. Some industrial applications also require bypass to enable operation in the event of a VFD failure, and typically are requested on centrifuges, induced and forced draft furnace fans and pumps.

In commercial buildings, fire and safety requirements often call for bypass as part of a VFD package to insure the evacuation of smoke from a building after a fire. In such cases, bypass must allow for the remote control of the motor.

The bypass must switch the power supply to the motor between the variable frequency drive and the power line, but it also must be able to:

- Protect the motor in both variable frequency drive and bypass modes.

- Interface with safety controls.

- Isolate the variable frequency drive for service while maintaining motor operation.

- Meet code requirements as a motor starter.

Many bypasses are sized to handle only the full load current of a motor and not the locked rotor current. These are less expensive contactors or switches but cannot act as motor starters. A bypass which is not horsepower rated must only be switched when power is off and therefore requires a motor starter upstream.

Post a Comment:

You may also like:

Featured Articles

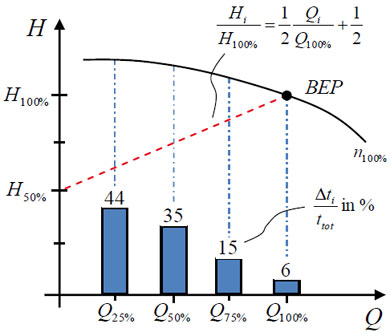

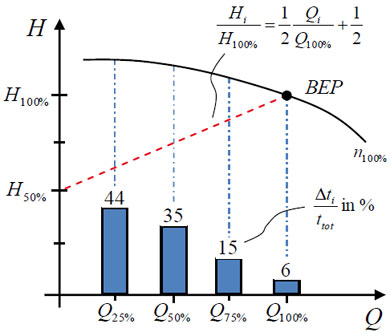

Variable frequency drive for water ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

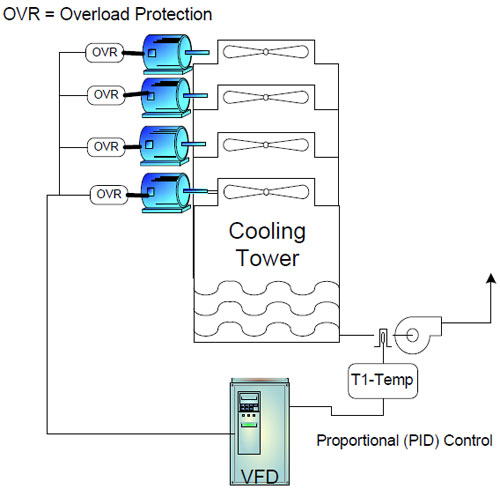

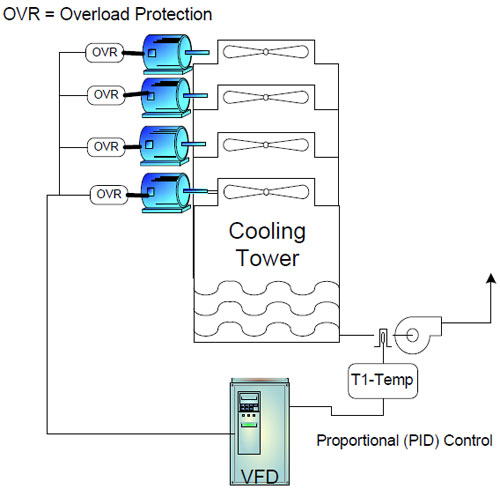

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...Single VFD for Multiple Motors

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...Select a right Variable Frequency Drive

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...VFD on air compressor considerations

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.