Variable Frequency Drive Efficiency

A variable frequency drive (VFD) is a device that controls the rotational speed of motor-driven equipment. Variable frequency drives efficiently meet varying process requirements by adjusting the frequency and voltage of the power supplied to an AC motor to enable it to operate over a wide speed range. External sensors monitor flow, liquid levels, or pressure and then transmit a signal to a controller that adjusts the frequency and speed to match process requirements.

PWM variable frequency drives are most often used in variable torque applications in the 1 to 1,000 hp motor size range. For centrifugal pumps or fans with no static lift, the fluid or air flow provided varies directly with the pump or fan rotational speed. The input power requirement varies as the cube or third power of the speed ratio. Small decreases in equipment rotating speed or fluid flow yield significant reductions in energy use. For example, reducing speed (flow) by 20% can reduce power requirements by approximately 50%.

hp1 = driven-equipment shaft horsepower requirement at original operating speed

hp2 = driven-equipment shaft horsepower requirement at reduced speed

RPM1 = original speed of driven equipment, in revolutions per minute (RPM)

RPM2 = reduced speed of driven equipment, in RPM

Flow1 = original flow provided by centrifugal fan or pump

Flow2 = final flow provided by centrifugal fan or pump

Determining Energy Savings

To establish the energy savings that are possible when a variable frequency drive is applied to a variable torque load, you must determine the load duty cycle, or percentage of time that the fan or pump operates at each system operating point. You must also know the efficiency of the VFD and the drive motor when the motor is operating partially loaded and at a reduced speed to satisfy variable flow requirements.

Variable and constant torque loads are expressed in terms of the shaft horsepower supplied by the motor. A motor "load factor" is the load imposed upon the motor by the driven equipment divided by the motor's full output rating. The load on the variable frequency drive is the actual power supplied by the device (shaft horsepower divided by the motor efficiency at its load point) divided by the rated output power. Manufacturers can provide efficiency values for variable frequency drives as a function of operating speed or load for both variable torque loads (centrifugal fans and pumps) and constant torque loads (cranes, hoists, and conveyors).

When considering electronic PWM variable frequency drives, you may use Table 1 to obtain efficiency values for VFDs of various ratings that supply power to motors connected to either variable or constant torque loads (more about VFD load types).

1. These efficiency values may be considered representative of "typical" PWM variable frequency drive performance. There is no widely accepted test protocol that allows for efficiency comparisons between different VFD models or brands. In addition, there are many ways to set up a variable frequency drive that can affect the operating efficiency.

Variable frequency drive efficiency decreases with decreasing motor load. The decline in efficiency is more pronounced with VFDs of smaller horsepower ratings. As shown in the following example, this reduction in efficiency is not as detrimental as it first seems.

Example

Consider a VFD coupled to a motor that delivers 20 hp to an exhaust fan when operated at its full rated speed. At 1/4 of its rated operating speed, the fan delivers 25% of its rated airflow, but requires only 1/64 of full load power. Even with the low VFD efficiency of 47%, with adjustable speed operation the power required by the fan and the variable frequency drive is only 0.66 hp.

Remember that the system efficiency is the product of the variable frequency drive efficiency, the motor efficiency at its load point, and the driven equipment efficiency (Esystem = EVFD x Emotor x EEquipment ). Efficiencies for integral horsepower NEMA Design A and B motors at full and part-load can readily be obtained from the U.S. Department of Energy's MotorMaster+ 4.0 software tool. Efficiencies for driven equipment must be extracted from the appropriate pump or fan performance curves.

PWM variable frequency drives are most often used in variable torque applications in the 1 to 1,000 hp motor size range. For centrifugal pumps or fans with no static lift, the fluid or air flow provided varies directly with the pump or fan rotational speed. The input power requirement varies as the cube or third power of the speed ratio. Small decreases in equipment rotating speed or fluid flow yield significant reductions in energy use. For example, reducing speed (flow) by 20% can reduce power requirements by approximately 50%.

hp2 = hp1 x (RPM2 /RPM1)3 = hp1 x (Flow2 /Flow1)3Where:

hp1 = driven-equipment shaft horsepower requirement at original operating speed

hp2 = driven-equipment shaft horsepower requirement at reduced speed

RPM1 = original speed of driven equipment, in revolutions per minute (RPM)

RPM2 = reduced speed of driven equipment, in RPM

Flow1 = original flow provided by centrifugal fan or pump

Flow2 = final flow provided by centrifugal fan or pump

Determining Energy Savings

To establish the energy savings that are possible when a variable frequency drive is applied to a variable torque load, you must determine the load duty cycle, or percentage of time that the fan or pump operates at each system operating point. You must also know the efficiency of the VFD and the drive motor when the motor is operating partially loaded and at a reduced speed to satisfy variable flow requirements.

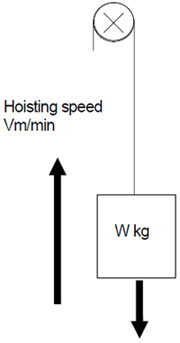

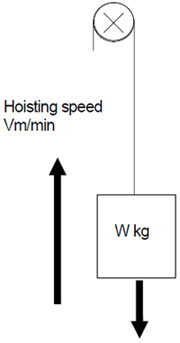

Variable and constant torque loads are expressed in terms of the shaft horsepower supplied by the motor. A motor "load factor" is the load imposed upon the motor by the driven equipment divided by the motor's full output rating. The load on the variable frequency drive is the actual power supplied by the device (shaft horsepower divided by the motor efficiency at its load point) divided by the rated output power. Manufacturers can provide efficiency values for variable frequency drives as a function of operating speed or load for both variable torque loads (centrifugal fans and pumps) and constant torque loads (cranes, hoists, and conveyors).

When considering electronic PWM variable frequency drives, you may use Table 1 to obtain efficiency values for VFDs of various ratings that supply power to motors connected to either variable or constant torque loads (more about VFD load types).

| VFD hp Rating | Efficiency,% | ||||||

| Load, Percent of VFD Rated Power Output | |||||||

| 1.6 | 12.5 | 25 | 42 | 50 | 75 | 100 | |

| 3 | 31 | 77 | 86 | 90 | 91 | 93 | 94 |

| 5 | 35 | 80 | 88 | 91 | 92 | 94 | 95 |

| 10 | 41 | 83 | 90 | 93 | 94 | 95 | 96 |

| 20 | 47 | 86 | 93 | 94 | 95 | 96 | 97 |

| 30 | 50 | 88 | 93 | 95 | 95 | 96 | 97 |

| 50 | 46 | 86 | 92 | 95 | 95 | 96 | 97 |

| 60 | 51 | 87 | 92 | 95 | 95 | 96 | 97 |

| 75 | 47 | 86 | 93 | 95 | 96 | 97 | 97 |

| 100 | 55 | 89 | 94 | 95 | 96 | 97 | 97 |

| 200 | 61 | 91 | 95 | 96 | 96 | 97 | 97 |

| 400 | 61 | 91 | 95 | 96 | 96 | 97 | 97 |

Variable frequency drive efficiency decreases with decreasing motor load. The decline in efficiency is more pronounced with VFDs of smaller horsepower ratings. As shown in the following example, this reduction in efficiency is not as detrimental as it first seems.

Example

Consider a VFD coupled to a motor that delivers 20 hp to an exhaust fan when operated at its full rated speed. At 1/4 of its rated operating speed, the fan delivers 25% of its rated airflow, but requires only 1/64 of full load power. Even with the low VFD efficiency of 47%, with adjustable speed operation the power required by the fan and the variable frequency drive is only 0.66 hp.

hp25% = (20 hp x (1/4)3 / (47/100)) = 0.66 hp.Note: This example does not account for the efficiency at each load point for the fan drive motor.

Remember that the system efficiency is the product of the variable frequency drive efficiency, the motor efficiency at its load point, and the driven equipment efficiency (Esystem = EVFD x Emotor x EEquipment ). Efficiencies for integral horsepower NEMA Design A and B motors at full and part-load can readily be obtained from the U.S. Department of Energy's MotorMaster+ 4.0 software tool. Efficiencies for driven equipment must be extracted from the appropriate pump or fan performance curves.

Post a Comment:

You may also like:

Featured Articles

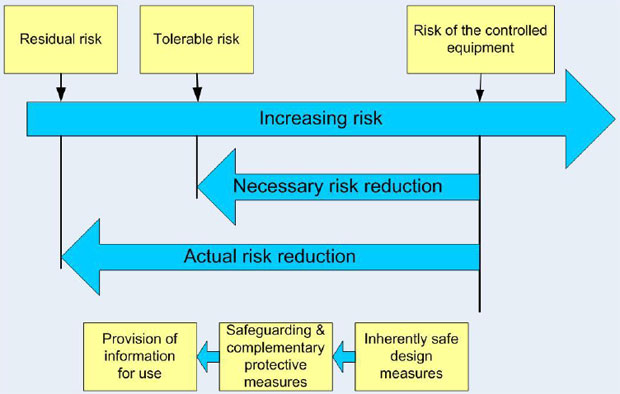

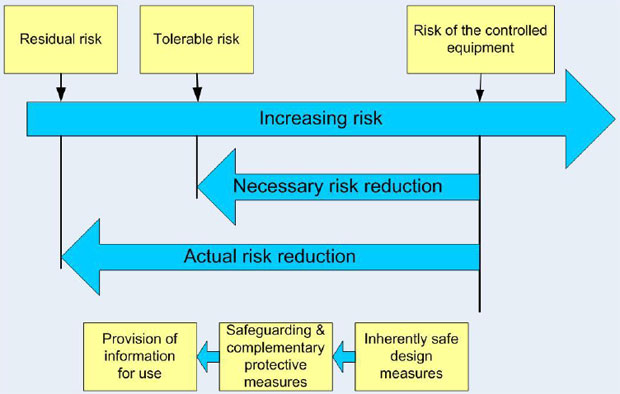

Variable Frequency Drive Basic Safety ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...Variable Frequency Drive Sizing

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.