Induction Motor and Variable Frequency Drive Inspection

Induction Motor

General-purpose motors and vector variable frequency drive (VFD) dedicated motors are three-phase induction motors. These motors mainly consist of a rotary shaft, bearings, stator winding and connection terminals. Vector VFD dedicated motors have an encoder at the rear of their rotary shaft. These components must be inspected periodically to prevent any fault from occurring due to the adverse effects from the operating environment, such as temperature, humidity, dust, dirt and vibration, changes in the parts with time, service life, and other factors.

Inspection items for an induction motor

It is recommended to check the following items periodically.

A service life of each part is as shown below. Note that the service lives shown below may differ depending on the operating conditions or environmental conditions. Replace faulty parts if found. For part replacement, contact a Gozuk service center or service station.

Variable Frequency Drive

A variable frequency drive (VFD) is a static unit mainly consisting of semiconductor devices. Daily inspection must be performed to prevent any fault from occurring due to the adverse effects from the operating environment, such as temperature, humidity, dust, dirt and vibration, changes in the parts with time, service life, and other factors.

Caution: For some time after the power is switched off, a high voltage remains in the smoothing capacitor. When accessing the inside of a variable frequency drive for inspection, wait until the charge lamp is turned off, and then make sure that the voltage across the main circuit terminals P-N is not more than 30VDC using a tester, etc.

Variable frequency drive inspection items

(1) Daily inspection

Basically, a daily inspection is to check for the following faults during operation.

Check the areas inaccessible during operation and those which require periodic inspection.

A service life of each part of variable frequency drive is as shown below. Note that the service lives shown below may differ depending on the operating conditions or environmental conditions. Replace faulty parts if found. For part replacement, contact a Gozuk service center or service station.

General-purpose motors and vector variable frequency drive (VFD) dedicated motors are three-phase induction motors. These motors mainly consist of a rotary shaft, bearings, stator winding and connection terminals. Vector VFD dedicated motors have an encoder at the rear of their rotary shaft. These components must be inspected periodically to prevent any fault from occurring due to the adverse effects from the operating environment, such as temperature, humidity, dust, dirt and vibration, changes in the parts with time, service life, and other factors.

Inspection items for an induction motor

It is recommended to check the following items periodically.

- Check if screws of the terminal block are securely tightened. Re-tighten if the screws are loosened.

- Check if there is no unusual noise generated from the bearings or brake of motors.

- Check if there are no damages or cracks in cables. Especially for operated motors, perform an inspection periodically in accordance with the operating environment.

- Check if the load connecting shaft has its axis without declination.

A service life of each part is as shown below. Note that the service lives shown below may differ depending on the operating conditions or environmental conditions. Replace faulty parts if found. For part replacement, contact a Gozuk service center or service station.

| Part Name | Standard replacement interval | Remarks | |

| General- purpose motor | Bearing | 20,000 to 30,000 hours | Standard replacement intervals are for reference. Replace faulty parts if found regardless of the standard replacement interval. |

| Grease | 20,000 to 30,000 hours | ||

| Forced cooling fan | 10,000 to 30,000 hours(2 to 3 years) | ||

| Vector VFD dedicated motor | Bearing | 20,000 to 30,000 hours | |

| Encoder | 20,000 to 30,000 hours | ||

| Oil seal | 5,000 hours | ||

|

Forced cooling fan |

10,000 to 30,000 hours(2 to 3 years) | ||

Variable Frequency Drive

A variable frequency drive (VFD) is a static unit mainly consisting of semiconductor devices. Daily inspection must be performed to prevent any fault from occurring due to the adverse effects from the operating environment, such as temperature, humidity, dust, dirt and vibration, changes in the parts with time, service life, and other factors.

Caution: For some time after the power is switched off, a high voltage remains in the smoothing capacitor. When accessing the inside of a variable frequency drive for inspection, wait until the charge lamp is turned off, and then make sure that the voltage across the main circuit terminals P-N is not more than 30VDC using a tester, etc.

Variable frequency drive inspection items

(1) Daily inspection

Basically, a daily inspection is to check for the following faults during operation.

- Check if the motor operates properly as set.

- Check for unusual vibration and noise.

Check the areas inaccessible during operation and those which require periodic inspection.

- Check if there are no abnormal signs in the cooling system. Clean the air filter, etc.

- Tightening check and re-tightening. Screws and bolts may become loose due to vibration, temperature changes, etc. Check and re-tighten them.

- Check the conductors and insulating materials for corrosion and damages.

- Measure the insulation resistance.

- Check and replace the cooling fan, smoothing capacitors and relays.

A service life of each part of variable frequency drive is as shown below. Note that the service lives shown below may differ depending on the operating conditions or environmental conditions. Replace faulty parts if found. For part replacement, contact a Gozuk service center or service station.

| Components | Standard Replacement Interval | Remarks |

| Cooling fan | 10 years | Standard replacement intervals are for reference.Replace faulty parts if found regardless of the standard replacement interval. |

| Main circuit smoothing capacitor | 10 years | |

| On-board smoothing capacitor | 10 years | |

| Relays | - |

Post a Comment:

You may also like:

Featured Articles

Variable Frequency Drive Sizing

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...Variable Frequency Drive Basic Safety ...

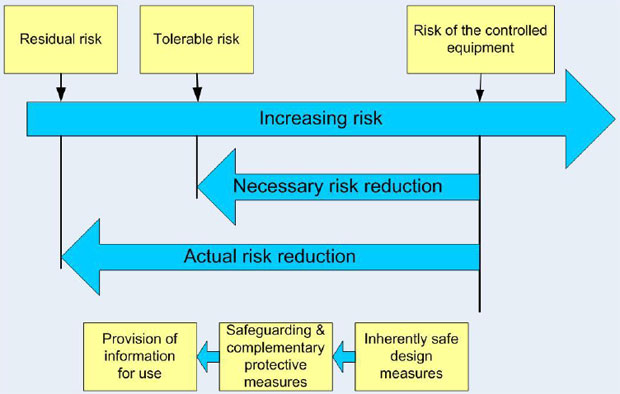

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.