The difference between VFD and Soft Starter

The difference with Soft Starter vs Variable Frequency Drive (VFD) is the method of starting employed.

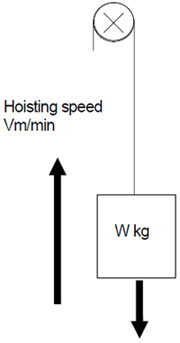

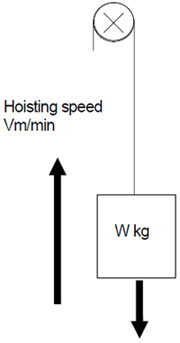

A soft starter reduces voltage, not Hertz, and as such the starting torque at 2-3 Hz is next to nothing. The soft starter is essentially robbing the motor of voltage at all points between 0 and 59 Hz, peak (Line) voltage met at 60 Hz. In overhead crane controls, setting a soft start to begin traversal motions with a capacity load on the crane or trolley can result in a 'jack rabbit' starting jump when the crane is unloaded. Or, setting it when unloaded can result in motor thermal trip and no motion achieved when the crane is then capacity loaded.

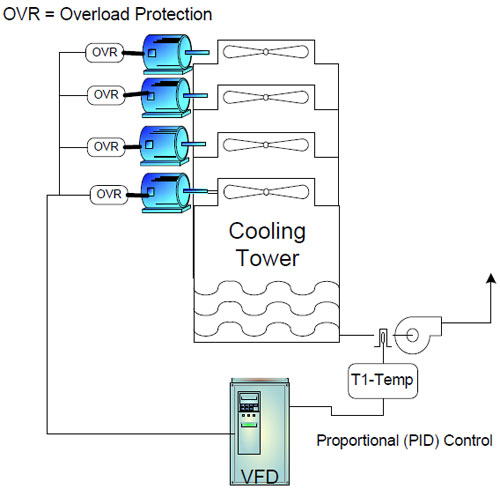

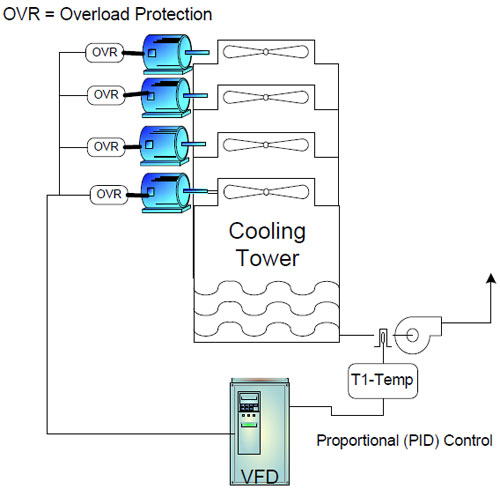

When compare with a variable frequency drive (VFD), the motor peak design ratio is basically preserved throughout the acceleration ramp. To put this in a general, simple explanation, when a 460 VAC/60 Hz motor is running at 30 Hz, the corresponding voltage to the motor should be in the vicinity of 230 VAC. Changing one value in the Volts to Hertz ratio without changing the other results in significant motor torque loss. A VFD will provide smooth starts from zero to peak speed as with the Hz/Voltage ratio maintained, near peak motor torque is preserved. Unlike a soft starter, it will provide the same balance ratio and control effect in a deceleration ramp as well.

We use many of the Gozuk variable frequency drives, as well as the gk3000 series VFDs depending on the method of operation and environment. For sizes above 30 Hp @ 460 VAC, and above 5 HP @ 230 VAC, the gk3000 series drives are the products.

A soft starter reduces voltage, not Hertz, and as such the starting torque at 2-3 Hz is next to nothing. The soft starter is essentially robbing the motor of voltage at all points between 0 and 59 Hz, peak (Line) voltage met at 60 Hz. In overhead crane controls, setting a soft start to begin traversal motions with a capacity load on the crane or trolley can result in a 'jack rabbit' starting jump when the crane is unloaded. Or, setting it when unloaded can result in motor thermal trip and no motion achieved when the crane is then capacity loaded.

When compare with a variable frequency drive (VFD), the motor peak design ratio is basically preserved throughout the acceleration ramp. To put this in a general, simple explanation, when a 460 VAC/60 Hz motor is running at 30 Hz, the corresponding voltage to the motor should be in the vicinity of 230 VAC. Changing one value in the Volts to Hertz ratio without changing the other results in significant motor torque loss. A VFD will provide smooth starts from zero to peak speed as with the Hz/Voltage ratio maintained, near peak motor torque is preserved. Unlike a soft starter, it will provide the same balance ratio and control effect in a deceleration ramp as well.

We use many of the Gozuk variable frequency drives, as well as the gk3000 series VFDs depending on the method of operation and environment. For sizes above 30 Hp @ 460 VAC, and above 5 HP @ 230 VAC, the gk3000 series drives are the products.

Post a Comment:

You may also like:

Featured Articles

Variable Frequency Drive Sizing

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...Single VFD for Multiple Motors

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...PWM Variable Frequency Drive ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...Variable frequency drive for water ...

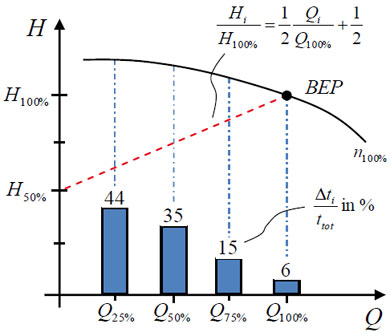

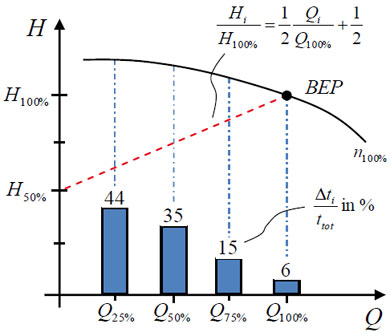

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...Variable Frequency Drive Basic Safety ...

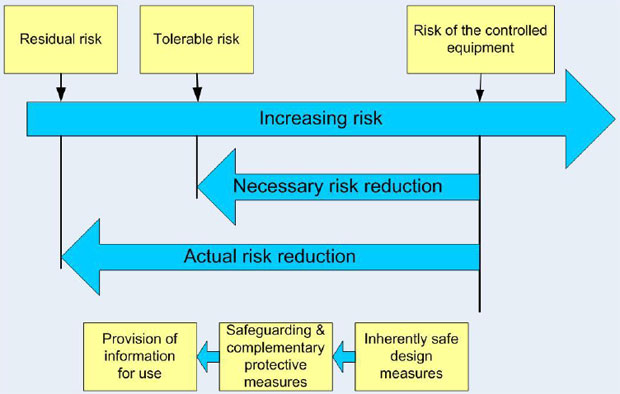

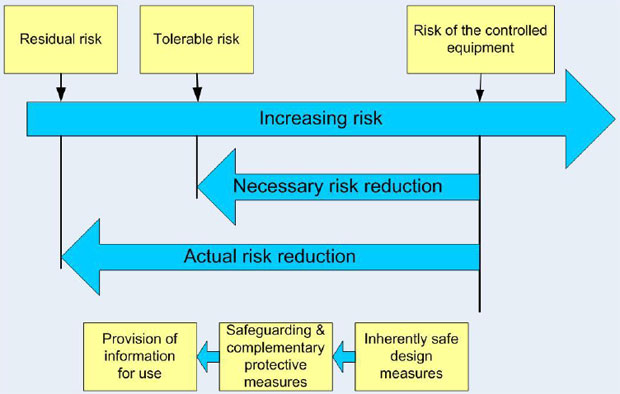

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.

Function: Soft starter make the motor in soft starting, like reduce inrush current. Besides of the motor soft starting, VFD also can control the motor speed, to save energy.

Cost: VFD's cost may be as high as triple as the soft starter.

If the motor works at full load all the time (means no need to vary the speed), then soft starter is your selection. In other case, say the ball mill works at 80% load, then choose the VFD, the saving energy will pay back to the VFD cost in future operation.